74 North Central Drive

O'Fallon, Missouri 63366

Telephone: (636) 272-1398

© 2017 All Rights Reserved

FROM CONCEPT TO REALITY

Most CNC machining equipment was originally designed for use on wood and metal substrates. If used properly, however, acrylic sheets, lexan or polycarbonates, UHMW, as well as many other plastic materials can be machined with the same tools and equipment, including mills files, engraving equipment, thread cutters, lathes, and reamers. At Bantry Plastics..

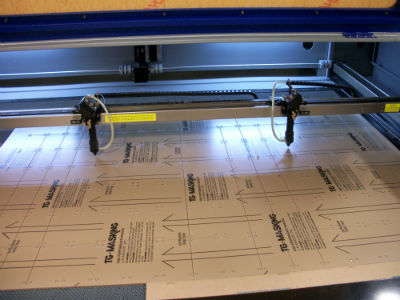

The use of lasers in acrylic processing offers unbeatable advantages in comparison with other technologies. Manual quality flame polishing of milled edges is cost and time intensive. The laser cut produces clear cut edges.

At Bantry Plastics, our large 43" X 63" bed allows us to optimize your projects with less waste. Our dual headed 80 Watt laser operates at twice the speed of a traditional laser machine.

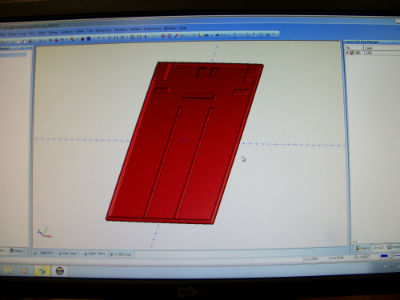

Although most customers prefer to provide their own drawings, Bantry Plastics is able to produce a CAD/CAM drawing for your projects if needed. We utilize BobCAD-CAM V 24 Software as well as a few other off the shelf software programs. Give us a call and let us help you with your next Acrylic, Plexi, Plexiglass, LEXAN, Polycarbonate, or other type of plastic design. From Concept to Reality.

Bantry offers our customers the added benefit of onsite assembly of products in order to cut down on lead times. From the simplest of assemblies to complex gluing, kitting, and bending, Bantry Plastics is eager to supply you with a finished product you will be proud of.

Thermoforming is a generic term for the manufacturing of plastic components through the vacuum and/or pressure forming processes. A simplistic overview of the single-sheet thermoforming process consists of heating an extruded sheet of plastic and either forming the sheet over a male mold or into a female mold.

Line bending plastic materials allows Bantry Plastics the opportunity to give our customers a finished product with few seams and less gluing. This process allows us to bend different types of materials into various angles and shapes giving the customer more solutions for their projects. Multiple stations allow for quicker deliveries without jeopardizing the integrity of the project.

Quick Turnaround and Competitive Pricing

Do you have wire and cable needs?